As a most used energy storage equipment,battery is getting more and more focus and research with the drain of traditional energy. In electric power industry, it is the key pillar that new energy can be used widely to replace fossil fuel drying up increasing. In automotive industry, it’s the core technology to replace combustion engine with electric engines; and it also becomes the key in these industries where electrification technology becomes the trend,such as ship, avionics, automotive etc. industries.

With the quick development of battery technology, battery modules have longer life and more energy density than before. On the other hand,Battery Management System (BMS) Technology is also facing new challenges like the monitoring and management of plenty of battery modules, the balance of battery modules, the temperature management,the performance control, security control and match technology between charging equipment and power depleting equipment.

Our BMS HIL solution covers the whole procedure from designing, developing to testing & verifying, and provides rapid control prototype for BMS in the designing and developing stages, which greatly improves the development efficiency and reduces the product cycle. At the same time, it also provides systematic testing for BMS in the testing & verifying stages, which ensures the completeness of product functions, stable performance, and improve the test's degree of automation.

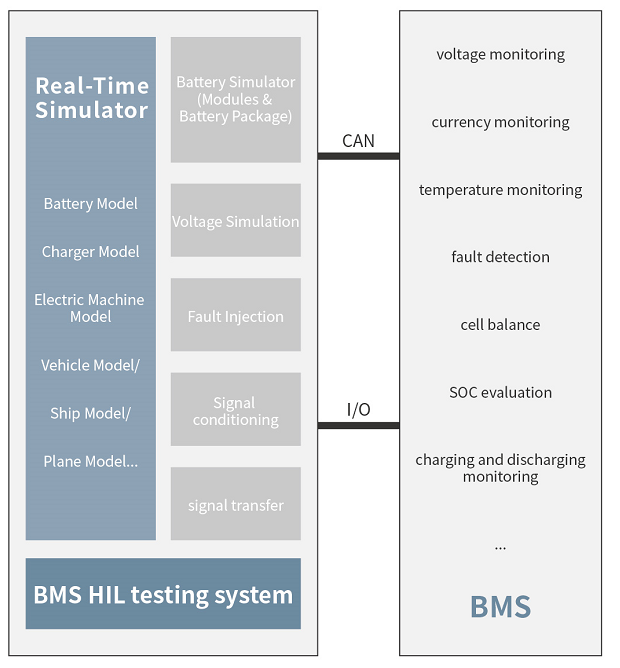

Keliang’s BMS HIL can achieve the CSC/LECU HIL to test the functions of bottom control units of BMS.This system works as the operating platform for model developing software,simulation and control software and monitoring and controlling software, and it consists of upper computer,simulator,battery package simulator and CAN communication module,and it can achieve the real-time calculation of battery and vehicle model and transmit the command of communication modules and expected value to battery simulator.Battery simulator simulates the output of battery modules,and transmit the results to simulator. Besides, it can also simulate other modules of vehicle and interchange data with BMS.

As the key factor of safety control and performance optimization ,the development and verifying of battery management system have to meet the system testing requirements to. ensure the functions perfect and performance stable.

And below are the main challenges of BMS testing tasks which should be simulated:

■ the real-time changing status of real battery modules

■ the real -time uneven status of battery for verifying the balance function

■ the real-time ultimate status such as fast charge and discharge, overvoltage, undervoltage

■ the real-time battery faults like short circuit,degradation to for verifying detection and process function

■ the real-time temperature of battery for verifying the temperature management function

■ the real-time status of other parts and communication with BMS

■ the real-time status of SOC

■ the real-time values for verifying the BMS results

■ the fast completion of repeatd test for dealing with multiple BMS test

■ flexible enough to configure different types of BMS and battery testing system

In order to systematically test the functions of BMS, using real battery packs for testing will not only cause a lot of waste of batteries, but also cause a lot of waste of labor and time in the inconvenient test process. Moreover, using real batteries can not create extreme conditions for testing, and can not achieve systematic testing and batch testing. The disadvantages indicate that it is not advisable to adopt the real battery pack for BMS systematic testing.

In view of the above problems in BMS testing, KeLiang proposed a solution of BMS hardware-in-the-loop system using battery simulator instead of real battery. The core idea of this scheme is to simulate all kinds of working conditions of batteries by combining high-precision battery simulator with real-time battery model, and to create a very real test environment for BMS by simulating other system modules with simulator and auxiliary equipment, so as to achieve a complete and effective BMS system-level test.

The system, as a systematic test platform of BMS, is applied to verify the following functions of BMS:

■ Battery charging and discharging control function

■ Total voltage and current monitoring function

■ Cell voltage monitoring function

■ Equalization function of single cell

■ Battery SOC evaluation function

■ Battery temperature management function

■ Battery safety control function

■ Fault diagnosis and processing function

■ Inter system communication function