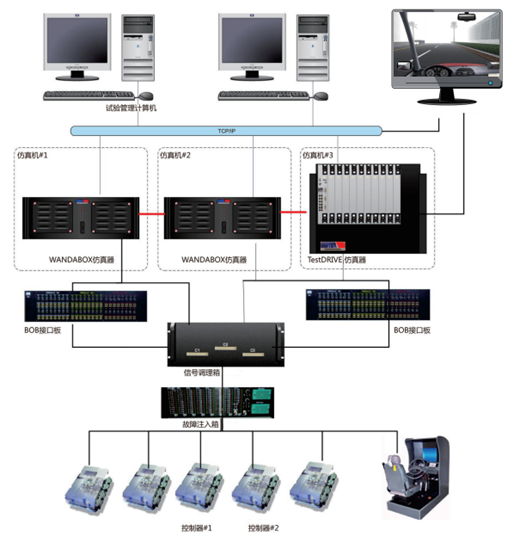

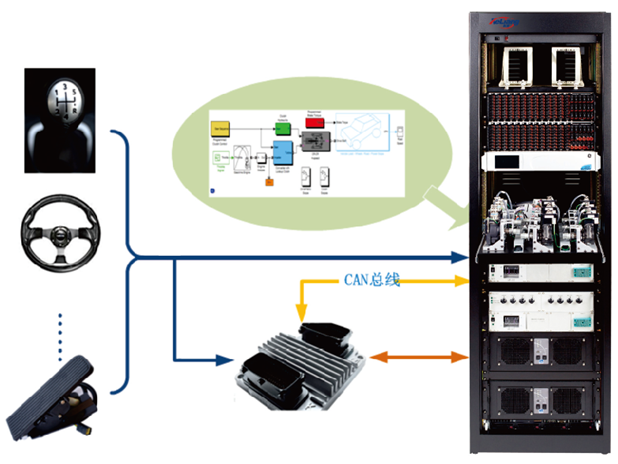

In the development of new energy automotive, it usually costs a lot of time, manpower and material resources, with large investment and long R&D period, to make overall design, overall performance analysis and control strategy of powertrain related controller and controller development. The application of HIL simulation technology provided by KeLiang can quickly establish the model of the system, evaluate the performance of the vehicle and optimize the parameters of each part. In the solution, parts of the actual controlled objects are replaced by simulation models running in real time on a high-speed computer, which also connected with the target controller to form a system to test and verify the functions of the control system. Our solution not only solves the problem that traditional offline simulation is too simple and ideal for simulating real conditions, but also reduces the time and labor cost.

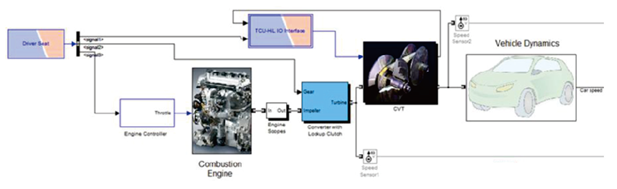

The power system solutions provided by KeLiang include engine EMS test, and other development tests regarding transmission (AT/AMT/CVT) controllers and vehicle dynamics.

■ Engine Control Unit (ECU/EMS) HIL Testing

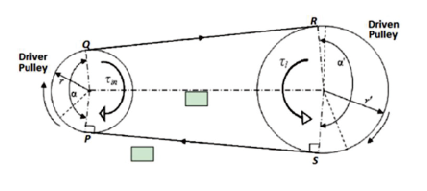

■ Transmission (AT/AMT/CVT) Testing

■ Vehicle Dynamics(EPS、ESP) Testing

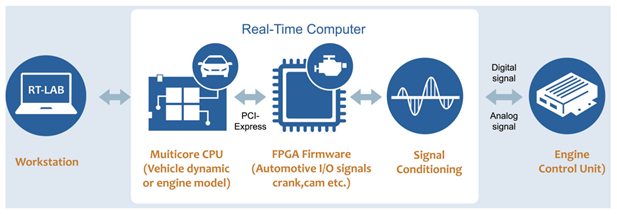

OPAL-RT’s real-time simulator connects FPGA with CPU by PCI-Express Link. Through FPGA, it can generate and capture signals with high accuracy, and then transmit them to multicore CPU after high-speed processing. High-speed CPU operation realizes a high response and low-delay closed-loop simulation through dynamic models operation.

The events capture module can accurately monitor the pulse signals’ rising/falling edge. In a typical engine management control system ECU, all the injection and ignition signals are processed by FPGA time processor module.

The synchronization model based on FPGA can simulate all the signals of a engine, including:

■ crankshaft

■ camshaft

■ starting signal

■ ignition signal

■ fuel loop signal

Knock sensor varies depending on the different forms of engine piston. FPGA knock signal analog module can simulate different knock conditions.

Powertrain HIL simulation system compacts the following leading industrial simulation model software packages:

■ CarSim

■ LMS Imagine. Lab

■ DYNA4 Engine Themos

■ AVL Cruise

■ GT-Power