As a common energy storage device, batteries are being increasingly researched and valued amid growing energy challenges. In the power sector, batteries serve as a key pillar enabling new energy sources to replace depleting fossil fuels and achieve large-scale application. In the automotive industry, batteries represent the core technology essential for electric vehicles to replace internal combustion engine vehicles. Across other fields such as marine, aviation and various industries undergoing electrification trends, battery technology has increasingly become a critical factor for development.

Alongside rapid advancements in battery technology, Battery Management System (BMS) technology also faces new challenges. The energy density, service life, and other characteristics of individual battery cells have seen leapfrog improvements, placing higher demands on BMS. Key challenges include monitoring and managing large numbers of cells, cell balancing management, battery pack thermal management, performance control, safety control, and compatibility technologies with charging and power-consuming equipment—all of which impose greater demands on BMS functionality and performance.

KeLiang provides a BMS hardware-in-the-loop (HIL) system solution that covers the entire process from BMS design, development, and test verification. During the design and development stages, it enables rapid prototyping of BMS functions, improving development efficiency and shortening the product cycle. In the testing and verification phase, the solution offers systematic BMS testing, effectively ensuring product functional completeness and performance stability. It also enhances test automation, significantly reducing R&D labor and time costs.

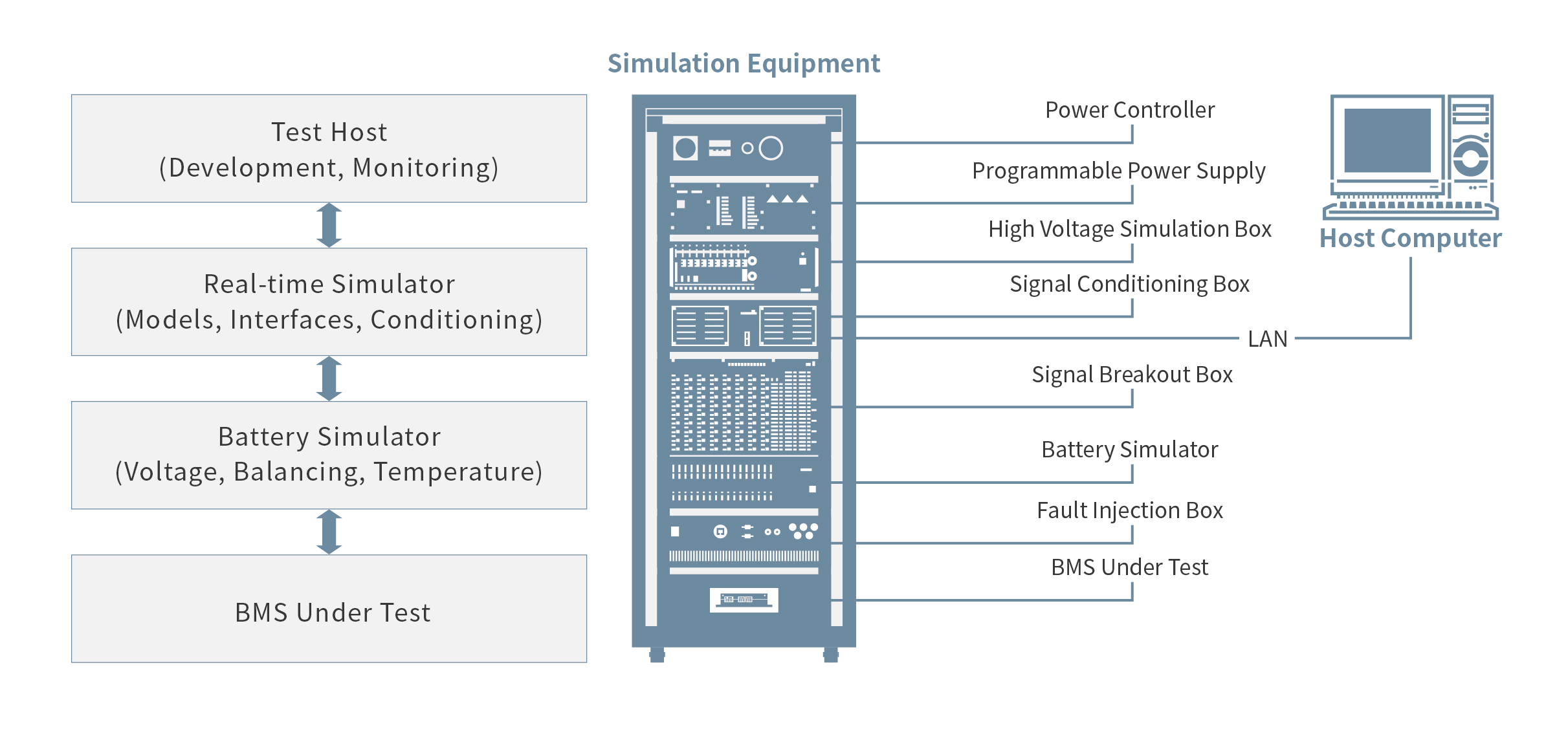

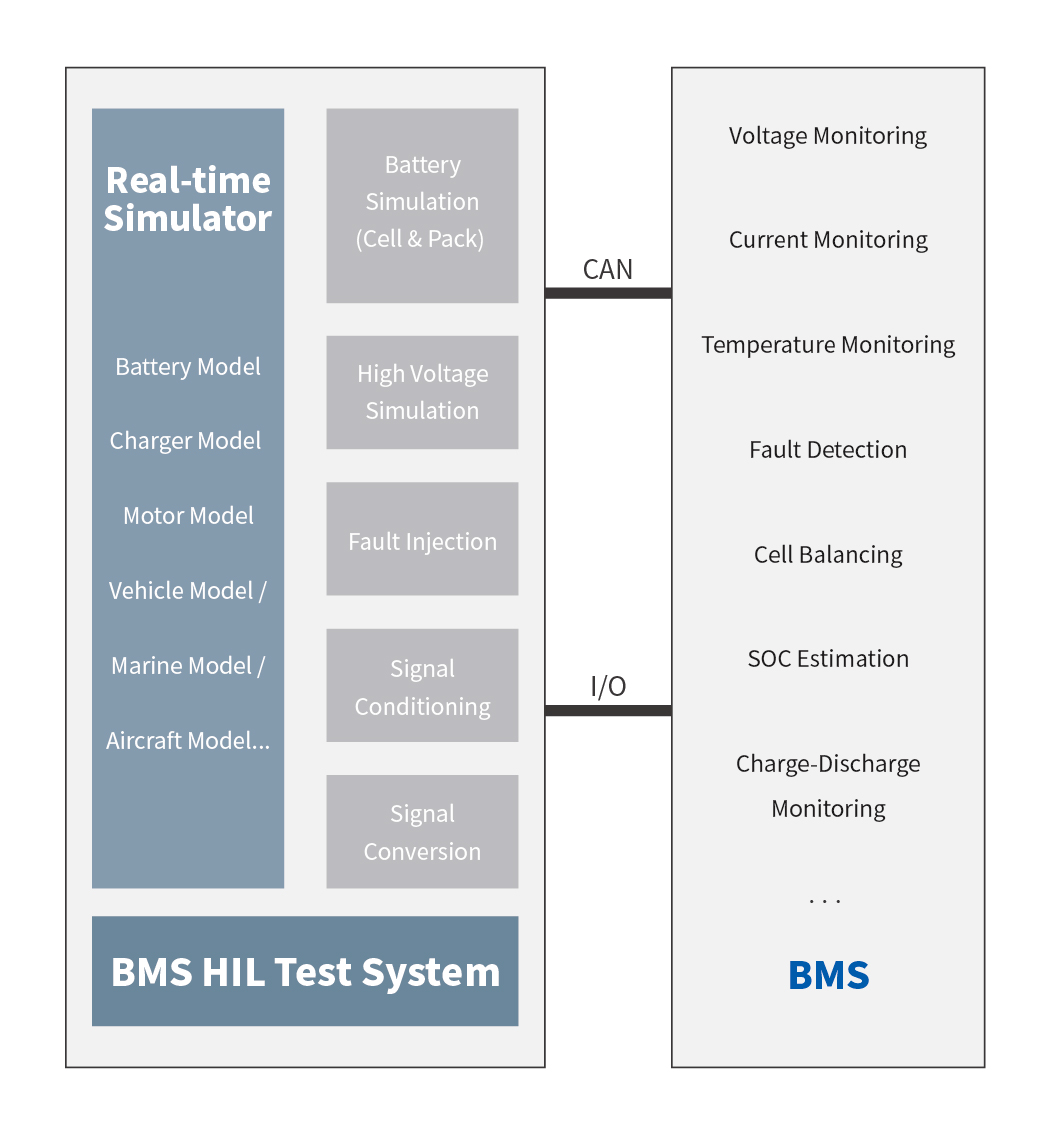

KeLiang’s battery management HIL test system simulates the output of individual cells within a vehicle battery pack to test the functionality of the BMS underlying control unit, enabling HIL testing of CSC/LECU (BCM). The system consists of a host computer, a real-time simulator, a battery pack simulator, and CAN communication modules, among other components. The host computer is used for simulation and test development, monitoring, and other functions, serving as the operating platform for model development software, simulation control software, and monitoring software. The real-time simulator executes real-time calculations for battery and vehicle models and transmits corresponding commands and expected output values to the battery pack simulator via communication modules. The battery pack simulator then reproduces the output of each cell and feeds back simulated results to the real-time simulator. Simultaneously, the real-time simulator can emulate other vehicle modules and exchange data with the BMS.

As a key factor in battery system safety control and performance optimization, the development and verification of a Battery Management System (BMS) product require systematic testing to ensure functional completeness and performance stability. BMS testing mainly faces the following challenges:

■ Simulating the real dynamic working states of battery cells in real time.

■ Simulating cell inconsistency in real time to verify balancing functionality.

■ Simulating rapid charge-discharge, overvoltage, and undervoltage conditions in real time to verify protection functions.

■ Simulating various battery faults (e.g., short circuit, aging) in real time to validate fault detection and handling capabilities.

■ Simulating temperature variations of the battery pack in real time to test thermal management functions.

■ Simulating the operation of other systems and interacting with the BMS in real time.

■ Rapidly adjusting battery states such as State of Charge (SOC) for multiple tests.

■ Enabling test equipment to synchronously measure true values to verify BMS result accuracy.

■ Facilitating repeatable tests efficiently for multiple BMS measurements.

■ Ensuring flexible and configurable test equipment to accommodate different types of BMS and batteries.

Using real battery packs for systematic BMS testing is not advisable. This approach not only leads to significant battery wastage but also consumes considerable time and labor due to cumbersome procedures. Moreover, real batteries cannot be used to create extreme test conditions, nor can they support systematic or batch testing effectively.

To address these BMS testing challenges, KeLiang proposes a BMS Hardware-in-the-Loop (HIL) system solution that uses battery simulators in place of real batteries. The core concept involves combining high-precision battery simulators with real-time battery models to simulate various battery operating conditions. Together with a real-time simulator and auxiliary equipment that emulate other system modules, this enables comprehensive and effective system-level testing of the BMS.

As a systematic BMS testing platform, this system is suitable for verifying the following BMS functions:

■ Battery charge and discharge control

■ Total voltage and current monitoring

■ Individual cell voltage monitoring

■ Cell balancing functionality

■ Battery State of Charge (SOC) estimation

■ Battery pack temperature management

■ Battery pack safety control

■ Fault diagnosis and handling

■ Inter-system communication