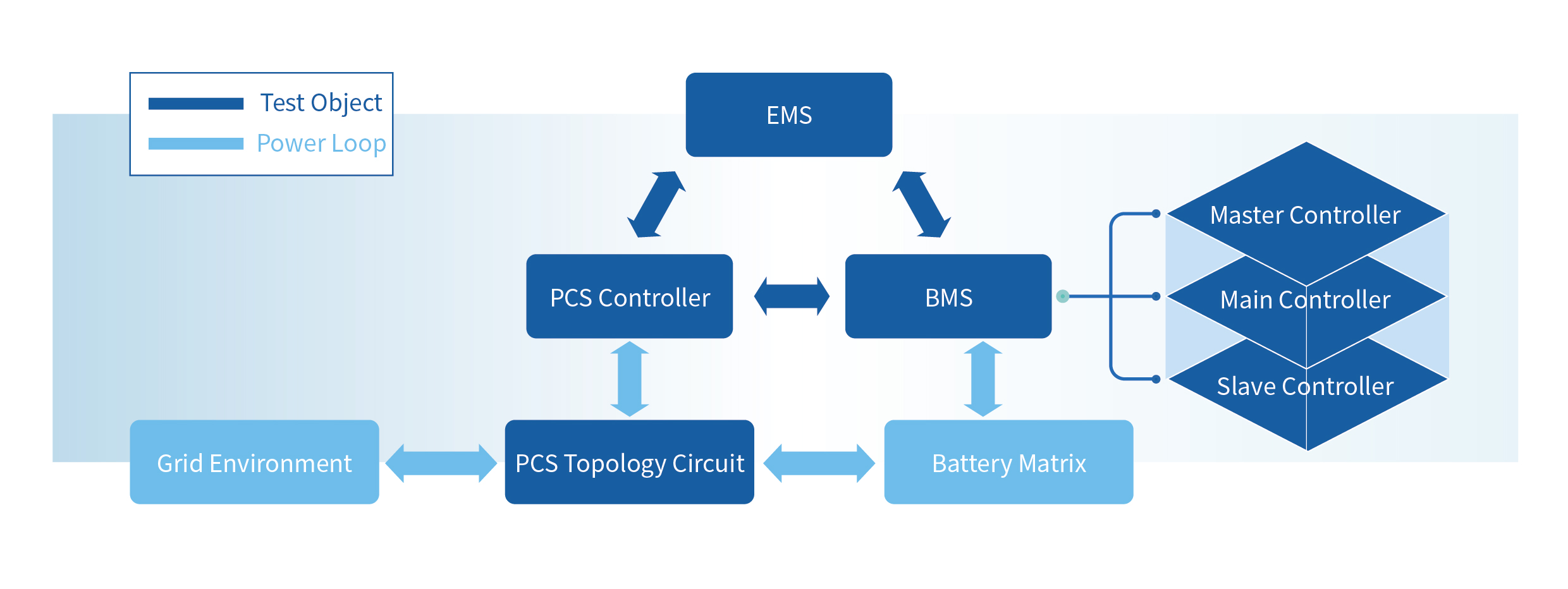

The control devices of an energy storage power station mainly include the Power Conversion System (PCS) controller, the Battery Management System (BMS), and the Energy Management System (EMS). The reliability of their functions is directly related to the safe and stable operation of the energy storage power station. Therefore, comprehensive testing and validation of the three-level control functions of the “PCS controller / BMS / EMS” are crucial.

To conduct thorough and accurate testing of the three-level control functions of the “PCS controller / BMS / EMS”, it is necessary to provide a test environment for the energy storage power station that includes the grid network topology and a realistic battery matrix. However, building a real-scale experimental scenario with an actual grid network topology and battery matrix is not only extremely costly and time-consuming, but also difficult to implement and inflexible. Moreover, it involves safety risks due to high-voltage and high-current testing under extreme operating conditions.

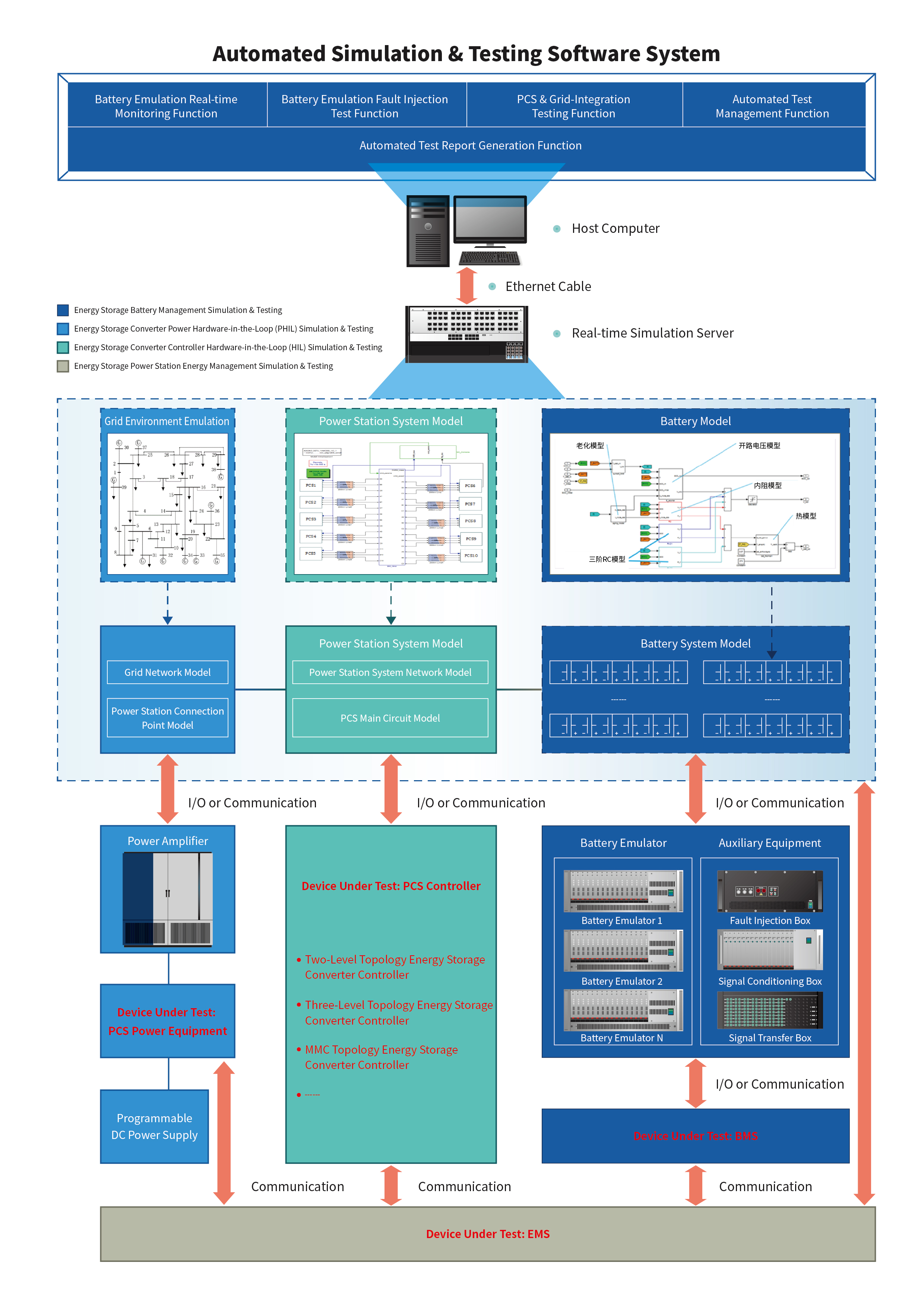

Therefore, KeLiang has constructed a complex test environment for energy storage converters and power stations, as well as a field grid environment model, based on an host computer (including an automated simulation test software system), a real-time simulation server (containing battery system models, power station system models, and grid network models), a battery simulation system and its auxiliary equipment, power amplifiers, and programmable DC power supplies. This setup enables Hardware-in-the-Loop (HIL) or Power Hardware-in-the-Loop (PHIL) simulation & testing for the entire energy storage industry chain, targeting the functions of the PCS controller, BMS, and EMS under test. It not only flexibly and efficiently simulates field grid conditions, but also safely, reliably, and rapidly builds complex test environment models for energy storage converters and power stations, including battery models, at low cost and with high efficiency. This provides full lifecycle test validation support for the research and development of key equipment and system integration in the energy storage industry, covering principle design verification, R&D process validation, factory acceptance testing, and on-site operation and maintenance analysis.

■ Employs distributed, modular design with excellent scalability.

■ Equipped with 2 Intel 4-core/3.8 GHz or 2 Intel 8-core/3.3 GHz high-performance, high-frequency CPU processors and 1 Xilinx Artix-7 FPGA processor. Supports expansion and distributed parallel real-time simulation high-performance computing via fiber optic or PCIe bus interconnection.

■ Features a user-friendly graphical interface supporting system modeling, modification, debugging, operation, result output, etc., making the entire simulation process intuitive and convenient.

■ Compatible with Matlab/Simulink, allowing the use of numerous Simulink module libraries, enhancing R&D and testing efficiency.

■ Supports various secondary development APIs such as C/C++, LabVIEW, Python, enabling user-defined component models.

■ Incorporates specialized power system real-time solvers (ARTEMIS), State-Space Nodal (SSN) method, power electronic device library for dedicated applications (RTeDRIVE), and specialized power electronic eHS (electrical Hardware Simulation) solver tools.

■ Supports multiple communication protocols including RS485, CAN, IEC 60870-5-104, Modbus, IEC61850.

■ Supports numerous third-party boards, such as PCI/PCI-E boards from commercial vendors like NI, MOXA, Softing. Also supports customized driver development for interface boards.

■ Supports simulation of extreme battery operating conditions for comprehensive functional testing of Battery Management Systems.

■ Supports Hardware-in-the-Loop fault ride-through (low-voltage ride-through, high-voltage ride-through, or consecutive high/low-voltage ride-through) functional testing for new energy equipment controllers, including energy storage.

■ Supports all-digital simulation testing by embedding dynamic link library models encapsulating control source code of new energy power electronic equipment (including energy storage) into the real-time simulation server.

■ Supports Power Hardware-in-the-Loop functional testing by connecting new energy power electronic equipment (including energy storage) to the real-time simulation server.

■ Supports real-time simulation testing via Hardware-in-the-Loop connection of hybrid energy storage systems (with multiple technology paths) and new energy plant/farm Energy Management Systems (including storage) to the real-time simulation server.

Features of KeLiang's full industry chain simulation & testing solution for energy storage systems are as follows:

■ Safe, reliable, flexible, efficient, and accurate system test environment simulation

Grid Environment Simulation: Electromagnetic transient real-time simulation to replicate real grid environments.

Grid Fault Simulation: Electromagnetic transient real-time simulation to replicate real grid environments.

Energy Storage Power Station Environment Simulation: Constructs network models identical to actual feeder topologies within energy storage stations. Integrates DLL-packaged PCS models for diverse energy storage technologies at grid-connection points, achieving high-fidelity mirroring of on-site grid-tie operation capabilities.

Energy Storage Converter Circuit Simulation: Detailed modeling of power electronic topology circuits with specialized solver tools.

Energy Storage Converter Function Simulation: Pre-charge function, current/voltage limiting, and other critical operations.

Communication Fault Simulation: Models communication failures among three-level controllers (PCS/BMS/EMS).

Battery Cell Voltage Simulation: Outputs actual voltage signals based on simulation model calculations.

Battery Internal Resistance Simulation: Configured in models to manifest in voltage-current relationships.

Battery SOC Simulation: Computed within models, manifested through voltage and internal resistance variations.

Battery Temperature Simulation: Receives calculation results from the simulation model and outputs temperature sensor signals.

Battery Charge/Discharge Current Simulation: Generates current sensor signals via model configuration.

Battery Fault Simulation: Simulates faults including battery short circuit, open circuit, aging, overcharge, and over-discharge.

Battery Balancing Simulation: Configures imbalance within the simulation model and monitors balancing current.

■ Systematic and Comprehensive Testing

Simulates various energy storage power station operating conditions to conduct steady-state functional testing.

Simulates various energy storage power station fault conditions to conduct transient functional testing.

■ Automated Testing

Repeatable tests.

Automated execution of the test process.

Saves labor and time costs, improving R&D and testing efficiency.

■ Various Battery Models: Lithium-ion battery, nickel-metal hydride battery, nickel-cadmium battery, lead-acid battery, flow battery, fuel cell models, etc.

■ Various Energy Storage Converter Models: Three-phase two-level topology, three-phase three-level NPC topology, three-phase three-level ANPC topology, DAB topology, LLC topology, cascaded H-bridge topology models, etc.

■ Various Power Station Models: Photovoltaic power station, wind farm, photovoltaic-plus-storage station, wind-plus-storage station, wind-PV-storage station, high-voltage cascaded energy storage station, flywheel energy storage station, flow battery energy storage station, hybrid energy storage station models incorporating different technology paths, etc.

■ Various Grid Models: Microgrid, distribution network, two-terminal pseudo-bipolar VSC-HVDC grid, two-terminal true-bipolar VSC-HVDC grid, four-terminal true-bipolar VSC-HVDC grid, UHVDC transmission grid, AC large power grid models.

■ Various Transmission Line Models: PI-section line, distributed parameter long line, frequency-dependent long line, short line models, etc.

■ Various Transformer Models: Single-phase two-winding linear transformer, single-phase three-winding saturable transformer, single-phase multi-winding transformer, three-phase two-winding transformer, three-phase three-winding transformer, three-phase multi-winding transformer, on-load tap-changing transformer, etc.

■ Various Load Models: Squirrel cage motor load, direct-drive motor load, constant impedance load, constant power load, etc.

■ Shanghai KeLiang Information Technology Co., Ltd. (headquartered in Shanghai, with branches in Beijing, Xi'an, and Changsha) possesses a nearly 300-person technical team with extensive experience capable of providing professional customized engineering services.

■ Leveraging long-term system application experience in fields like energy storage and new energy, along with effective technical communication and exchange with domestic and international peers, the company has successfully applied its series of products and technologies—"real-time simulation, rapid control prototyping, real-time testing"—widely in power electronics, new energy, power systems, and integrated energy. This demonstrates the capability to provide clients with complete real-time simulation and test diagnosis system solutions and implement them in engineering applications.

■ The company possesses engineering experience advantages in undertaking technical consultation, solution design, system integration, software/hardware development, and related technical services for various simulation and test engineering projects.